10 Precautions You Must Take When Loading/ Unloading a Truck

Trucking business is an enthusiastic profession. It is an amalgamation of excitement, thrill and above all precision and precaution. Though trucking industry gives you a breakthrough opportunity to wander about carelessly and to explore the world and brings you in contact with the nature’s perfect beauty; it demands a careful implementation of proper steps required to complete any target.

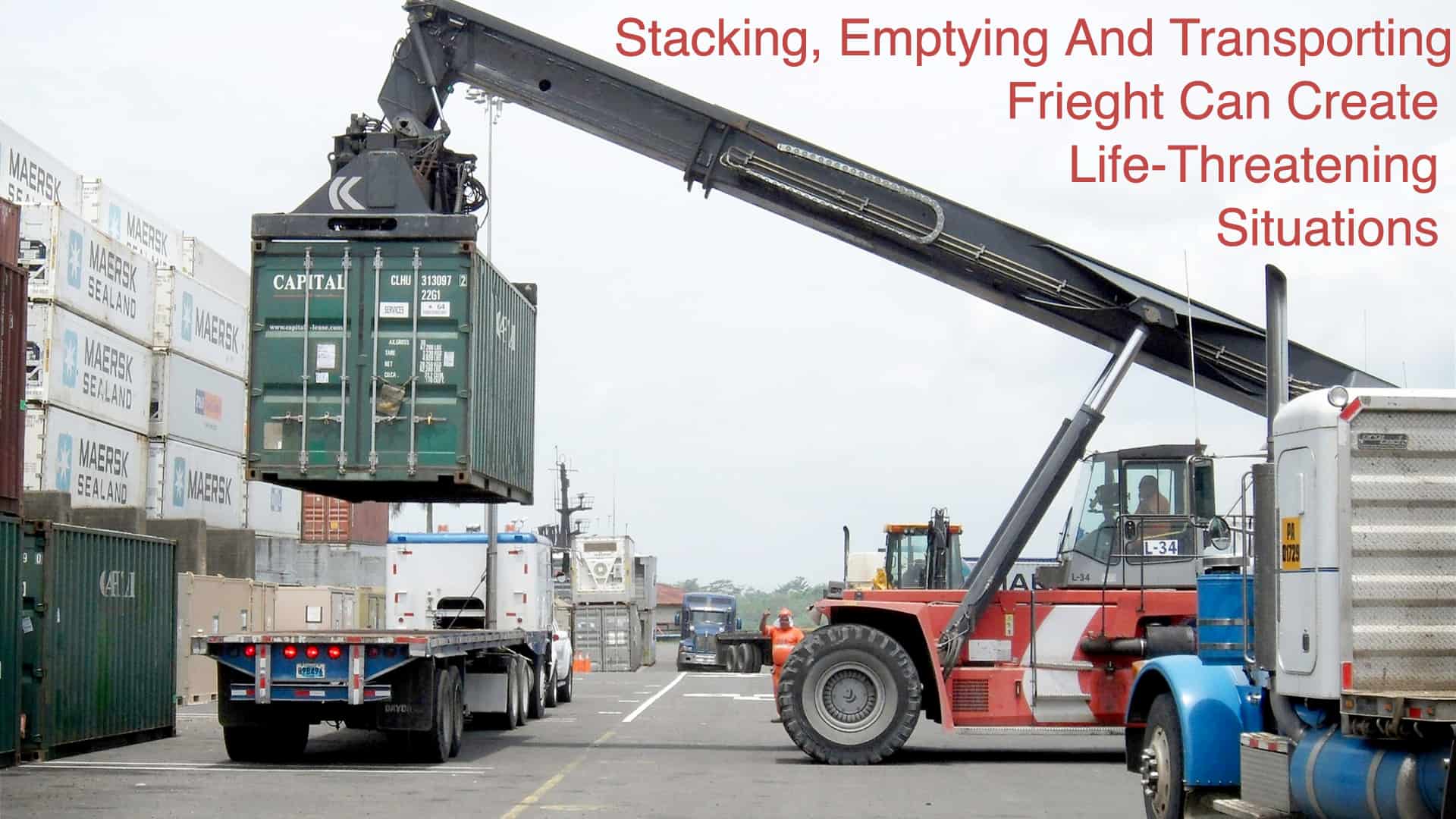

If one doesn’t follow the proper precautionary measures, he/she can face life threatening situations. Transporting loads is the major motive of the trucking business. It is an extremely perilous task. It may appear like a straightforward assignment of getting stuff from one place and hauling it to another place. But, stacking, emptying and transporting freight can cause genuine damage and even fatality. Workers stacking and emptying loads are presented with a genuine threat of substantial items hitting them or falling on them. It’s important for truckers to follow correct stacking and emptying methodology for security of self and others.

Drivers may meet mishaps if they don’t drive securely when hauling heavy and overwhelming loads. A similar thing can happen if the heaviness of the payload isn’t circulated well, subsequently bargaining the driver’s control of the vehicle. What makes transporting loads more unsafe is the likelihood of gambling lives of different drivers out and about. This can happen when loads are not safely attached to the vehicle and they ultimately end up moving onto the road and hitting different vehicles or impeding their way.

On relatively every considerable development venture, forklifts are utilized to move materials and these workhorses require cautious wellbeing safeguards.

“The Bureau of Labor Statistics reports that in the United States, almost 100 workers are killed and another 20,000 are genuinely harmed in forklift-related occurrences every year. Stacking and emptying materials is of specific concern despite the fact that forklift upsets are the main source of fatalities including forklifts; they speak to around 25% of all forklift-related deaths.”

A careless attitude while loading or unloading a truck can cause severe health hazards like:

- Unconsciousness resulting from inhalation of poisonous gases such as carbon monoxide from trucks.

- One can also suffer from back injuries due to improper lifting and carrying.

If there is an activity that can bring about a damage or a close miss, that activity ought to be ceased immediately and the supervisor should be informed about the occurrence. The boss should then exhort an administration agent instantly. The first preference must be given to any harmed work force and amending or isolating any peril coming about because of the incident to guarantee others are not placed in any threat. Employees and truck drivers must stay (where it is safe for them to stay) at the location of the incident where it actually occurred. But, the prime intention should be to prevent such damages. There is an utmost necessity to follow some preventive steps for avoiding the above mentioned unwanted incidents.

If you want a better trucking experience, try to be ready with all the tools and techniques. Along with knowing about the precautions that you must take when loading/unloading a truck, you should know several other things as well:

Managing the traffic conditions

A traffic administration plan for the assignment must be discussed between the included members, before stacking and emptying. The traffic administration plan and proper controls to be actualized ought to be talked about, including traffic cones assigning particular work regions and safe zones.

Work Zones

The work zones should be driver safe zones where proper system of communication can be established. The loading and unloading operations should be done keeping in mind the comfort level of each and every employee as well as the other pedestrians.

Cell phone Use

Cell phone use is to be constrained and limited just to operational needs and must not be utilized inside the work zone. It is perceived that supervisors are required to utilize mobiles all the more and for much of the time for operational reasons. Chiefs must guarantee it is protected to accept the call and they should leave the work zone and/or accept the call in the stamped safe zone.

Reasonableness of pallets or sacks

Prior to lifting any freight, the particular risks related with the load must be considered. Sorts of risks to consider include:

- steadiness of the thing

- restriction of load on pallets (Note: plastic therapist wrapping is not reliable and cannot guarantee freight and pallet uprightness)

- strength of packaging of pallets

- quality of sacks/handles

- lifting hardware suitability (fit for reason and certified).

If the danger related to the freight can’t be dispensed with or tended to, the payload ought not be lifted and must be reported to the Supervisor or Management delegate.

Description of Load

The detailed description and mass of load must be separately mentioned. In many occasion . there will also be distinguishing imprints or stickers on the freight.

Major Precautions To Be Taken While

Loading/Unloading A Truck

After being assured about the above stated things, you should now focus on the major precautions taken while loading/unloading a truck:

1. Know about Trucks Backing in to The Loading Zone

Continuously know about your environment, particularly when huge trucks are included. In the event that a truck is backing up, make tracks in an opposite direction from the stacking zone as it is hard for the driver to see behind the Hold up until the point that the truck has arrived at a total stop to wander into the stacking zone.

2. Make sure All Loads Are Properly Secure

All items in a truck should be anchored before taking off. If in any case they are not safe and secure, any movement can cause the objects to break in the Be sure your heaps are secure by utilizing load bars, vertical backings and street lashes.

3. Avoid The Loading Zone While Machines Are In Use

When you are walking close by or in the truck-loading area, you have to escape the way while machines are stacking/emptying the truck. Machines are capricious now and then and you never know when one would breakdown, causing some serious wounds or fatalities. It’s best to avoid such scenarios by keep the loading zone while machines are busy doing their task.

4. Ensure All Gap In The Areas Where Trucks Are Being Loaded

When you are stacking or emptying a truck, it may be really tough to see precisely where you are venturing. Along these lines, if there is a hole or drop off, you doubtlessly won’t have the capacity to see it, which creates the risk for fall damage. You have to secure these holes and drop offs before you begin truck loading and unloading. Only then, you can move with certainty, knowing your load won’t

5. Utilize Proper Lifting Techniques

Utilizing the correct lifting method avoids work environment mishaps and wounds. Always keep your posture right. Dead weight should always be lifted in the deadlift position. Another tip is to keep the items near you, which gives you more control over them and limits the probability of dropping them.

6. Lifts are to be scratched off the manifest and any errors noted

If in any condition, there is a weight disparity, guarantee that the proper people are informed, including truck administrators who may need to exercise alternative load control.

7. Things Put Away From The Danger Line

Any heaps or things put on the wharf from a vessel or truck must be put in an arranged manner and well cleared off the risk line, considering great housekeeping practices. No things are to be put away on or inside the danger line.

8. Skilled Workforce Used

Loading/emptying freight by forklift is to be finished by the designated skilled forklift administrator using safe zones and work territories.

9. Assessment of Stacking Zones and Vehicles

Stacking zones ought to be firm, level and completely free from irregular surfaces, potholes and different blocks that may cause slips or other dangers. It’s important to assess the vehicle and ensure that horns, reflectors, lights and other security highlights are in good condition.

10. Vehicle Examination

Keep a check on the perilous parts of the vehicle. For example, chain drives, control take-off and uncovered exhaust pipes. Prior to stacking, it is important to ensure that the vehicle is braked and balanced out.

There are numerous ways by which you can prevent unwanted incidents while loading/unloading a truck. The above mentioned steps are few important ones that will surely help you avoid dangerous and threatening situations. After all, life is the most precious asset one can have. Therefore, it is our prime responsibility to ensure proper safety of each and every one of those actively engaged in making the trucking business a success.

© 2008-2018. All Rights Reserved by Cunningham Trucking, Inc. & Westernston, Inc.